The Government Hates Greenwashing: What EPR Really Means for Your Packaging

The clock is ticking.

Four U.S. states have already passed Extended Producer Responsibility (EPR) laws targeting packaging, and Oregon’s first major compliance deadline—July 1, 2025—has come and gone. More states are following fast, with legislation introduced or under review in at least half a dozen more.

If your brand sells packaged goods, especially pet food or supplements, it’s no longer a matter of if you need to act, but how soon.

And let’s be honest: sustainability messaging is crowded with feel-good claims that often don’t hold up. That’s exactly what these new laws aim to address; EPR isn’t just about recycling, it’s about accountability. The era of greenwashing is winding down, and brands that can’t back up their packaging claims with real data may end up paying the price.

Still feeling like EPR is a vague legal maze? You’re not alone. Even packaging professionals are overwhelmed by the jargon, the fine print, and the moving parts. But the consequences (fees, fines, and operational headaches) are real.

Pro Tip: Not every brand will be on the hook for EPR fees right away.

Most state EPR laws include exemption thresholds based on annual revenue and packaging volume. In other words, smaller brands may not face the same reporting or fee obligations as larger producers. If you’re unsure where you land, rePurpose Global offers a quick assessment tool to help smaller and mid-sized brands navigate emerging EPR requirements.

So, let’s break it down. No legal briefs, no 50-page PDFs. Just the things you actually need to know to protect your business and move forward with confidence.

What Is EPR? (No Legal Degree Required)

Extended Producer Responsibility (EPR) is an environmental policy that shifts the cost of managing packaging waste from taxpayers and local governments to the producers, typically brand owners or importers.

In plain terms?

- It’s basically a packaging tax.

- The less recyclable your packaging is, the more you’ll likely pay.

These laws aim to reduce environmental impact by encouraging companies to use more sustainable packaging, maintain accurate records, and support effective recycling systems. That means your material choices, recyclability claims, and even label language now have direct cost implications.

Photo by wutzkoh

Four Fast Facts You Can’t Ignore

- EPR is the law. This isn’t a voluntary green initiative. It’s mandatory in participating states.

- You’ll pay fees based on the amount and type of packaging you put into the market. Those fees fund recycling, sorting, and waste recovery programs.

- Data is king. Without accurate, standardized packaging data, compliance becomes challenging, and audit risks increase.

- EPR isn’t new. It has been around for decades, first emerging in Europe in the early 1990s, with Sweden and Germany spearheading action on packaging waste.

Now that you know what it is, let’s discuss where it’s happening and why it matters more than ever if you sell in these states.

Warning: This section is tightly packed with details. Let’s unwrap it together (packaging pun intended).

Where It’s Happening: The State-by-State Reality

As of mid-2025, four states have passed EPR laws for packaging:

|

State |

Status |

Key Notes |

|

Law passed in 2021 |

First in the U.S. to adopt packaging EPR law. Reporting begins May 2026 for 2025 data. |

|

|

Oregon |

Active |

First major compliance deadline hit on July 1, 2025. |

|

Finalizing rules |

Producer fees expected to begin in 2026. |

|

|

Complex rollout |

Includes additional labeling and data standardization requirements. |

Other states, including Minnesota, Washington, and New York, have active or pending legislation. The pressure is building, and brands operating nationally can’t afford to take a wait-and-see approach.

Is Federal EPR on the Horizon? Just Look at Europe

While there’s no national packaging EPR law on the books yet in the United States, the momentum is real.

The U.S. Environmental Protection Agency (EPA) has signaled growing support for EPR-style regulations. In its 2023–2024 National Strategy for Preventing Plastic Pollution, the EPA outlined goals that include:

- Expanding producer responsibility

- Improving recyclability labeling

- Creating more uniform national data systems

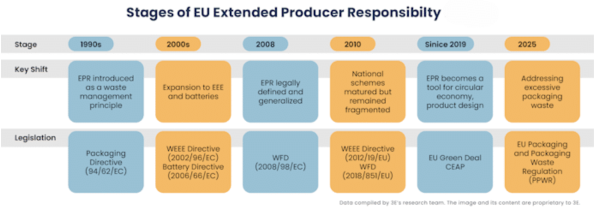

In April 2025, the EPA opened public dialogue on EPR legislation for batteries. It may seem narrow, but it reflects the same path EPR followed in Europe: beginning with batteries, expanding to electronics, and eventually evolving into a full packaging directive.

Caption: European EPR Legislative Timeline — beginning with formal packaging regulations (PPWD), then expanding to batteries, electronics, and other waste streams. (Source: 3eco.com)

Europe established the groundwork with the Packaging and Packaging Waste Directive (PPWD) in 1994. This laid the foundation for packaging recovery and recycling targets across member states. That framework evolved, eventually giving rise to Packaging and Packaging Waste Regulation (PPWR), which is a harmonized, legally binding framework across all EU member states.

By contrast, the U.S. is still in a patchwork phase. Each state is building its own rules, with different definitions, exemptions, timelines, and fee structures. For brands operating nationally, this means more risk, more complexity, and a greater reason to get ahead of it now.

Still with me? This stuff makes even packaging pros sweat. But you don’t need to memorize every regulation, just understand the direction it’s headed.

Now let’s get practical—because this is where packaging data becomes your secret weapon.

Photo by Elisau

Packaging Data: The New MVP

Accurate packaging specs are no longer just “nice to have.” Under EPR, they’re essential.

Your data should capture:

- Material composition by weight

- SKU-level packaging details (closures, liners, films, adhesives—yes, even that)

- Harmonization across brands and product lines so your reporting doesn’t turn into a multi-tabbed nightmare

This is where packaging engineers become invaluable. We translate component-level specs into actionable, reportable data.

Many companies rely on comprehensive enterprise systems, such as SAP, for managing product data. While powerful, these platforms can make it challenging to extract or update packaging details quickly, thereby complicating compliance workflows.

Specialized packaging specification management tools, such as Specright, are designed to address these challenges, including centralizing packaging materials data, tracking real-time changes, and streamlining standardization across SKUs and suppliers. These features can be especially helpful for managing EPR compliance.

Specright has also partnered with Lorax Compliance, a firm recognized for its deep regulatory expertise in EPR and sustainability. This collaboration reflects a broader industry shift toward integrating data and compliance systems—a direction that we believe pet food brands should closely monitor.

I was introduced to the platform early in my career through demos and exploratory conversations. Based on this, it was clear it had strong potential to support packaging teams navigating complex data and compliance needs. I’ve also reviewed their educational resources and webinars focused on EPR, which offer valuable insights for brands preparing for the next compliance phases:

If packaging data management is a challenge for your brand, these tools and resources can be a smart starting point for exploring solutions.

Why Design Now Impacts Your Bottom Line

EPR programs often use modulated fees, meaning your packaging design affects how much you’ll pay.

Lower fees ($):

- Mono-material formats (PET, PE)

- Clear and verified recyclability

- Accurate labeling (e.g., How2Recycle or state-mandated language)

Higher fees ($$$):

- Multi-material films or laminated pouches

- Packaging incompatible with material recovery facilities (MRFs)

- Vague or unsubstantiated recycling claims

In other words, better design equals lower fees. More sustainable materials, fewer surprises.

Photo by TonyTheTigersSon

Shelf Life vs. Sustainability: Why Pet Packaging Isn’t (Yet) Built for EPR

Here’s the hard truth: many pet brands still rely on packaging formats that EPR programs are actively trying to phase out.

Common challenges:

- Flexible films and laminates are often unrecyclable due to mixed materials

- Barrier structures that are critical for pet food’s shelf life usually lack viable end-of-life solutions

- Pouches with zippers, spouts, or valves complicate recovery and inflate EPR fees

It’s not about perfection, but about identifying opportunities for improvement that won’t compromise product performance or food safety.

Want a candid look at these challenges? Check out our recent Barking Mad podcast episode, “Is Recyclable Pet Food Packaging a Lie? Unraveling the Pet Industry’s Plastic Waste Problem.” It dives into what’s recyclable, what isn’t, and why it’s more complicated than most consumers (and brands) realize.

What Brands Should Be Doing Right Now

- Audit your packaging – Know exactly what materials and formats you’re putting on the market.

- Standardize specs – Harmonize packaging data across SKUs, brands, and suppliers for easier reporting.

- Align formulation with packaging – In pet food and supplements, material changes must protect shelf life, nutrients, and safety. Packaging engineers and formulators should work hand in hand.

- Collaborate smartly – Involve packaging engineers for design feasibility and legal/regulatory experts for compliance clarity.

- Rethink materials – Improving recyclability can lower both fees and environmental impact.

- Skip the greenwash – Only make sustainability claims you can prove.

Looking Ahead: Be Proactive, Not Reactive

EPR is evolving rapidly, and the reality is that most companies aren’t fully prepared. But don’t panic, you don’t have to scramble. Whether it’s improving packaging specs, conducting recyclability assessments, or simply mapping your risk, there’s still time to take smart, strategic action.

This is a competitive opportunity—greenwashing doesn’t work in a world where detailed packaging data is mandated. Brands that invest in real transparency now will be the ones that stand out later.

If your packaging team isn’t in the EPR conversation yet, they should be. And if your brand doesn’t know how to start, we can help.

At BSM Partners, we recognize that navigating EPR requires detailed expertise and ongoing learning. We work closely with brands to develop tailored strategies that address unique packaging and compliance challenges, helping you make confident, informed decisions every step of the way.

Follow us on LinkedIn for the latest updates on all things happening here at BSM Partners.

About the Author

Oksana Lylak is the Director of Packaging Engineering at BSM Partners, offering over 20 years of experience across industries like automotive, consumer packaged goods, and pet food. Oksana specializes in developing innovative, cost-effective packaging solutions. Passionate about sustainability and pet food packaging, she combines technical expertise with a solution-driven approach to drive industry advancements.

This content is the property of BSM Partners. Reproduction or retransmission or repurposing of any portion of this content is expressly prohibited without the approval of BSM Partners and is governed by the terms and conditions explained here.