No Heat, Still Processed: The Truth About Raw Pet Food

As the pet food market continues to expand, debates around the quality and safety of different product formats have intensified. A particularly common point of contention lies between “minimally processed” options, like raw pet food, and more “highly processed” formats, such as extruded kibble.

While raw pet food is often perceived by consumers as unprocessed, raw pet food still undergoes several important processing steps, including chopping or grinding, pathogen-reduction measures when applicable, and freezing. Advocates for raw pet food often frame processing as something to be avoided rather than understood, but processing is a key factor in the safety, quality, and formulation of all pet foods, including raw.

Pet food processing is important for several reasons:

- Food safety: Protecting both pets and the people who handle their food through validated kill steps or other safety controls

- Nutritional consistency: Improving digestibility and nutrient bioavailability through processes like cooking or grinding, and by neutralizing antinutrients

- Shelf stability: Preventing spoilage and extending usable shelf life

- Palatability: Developing textures and flavors that encourage acceptance

- Consumer convenience: Offering ready-to-feed, portable, and easy-to-store products

Raw pet food must address the same fundamental objectives as cooked or shelf-stable formats, but in different ways. Understanding its advantages, limitations, and obligations requires understanding both the production process and how manufacturers navigate these challenges without traditional thermal processing.

Photo by Chalabala

Pathogen Reduction Strategies in Raw Pet Food

Because raw pet food does not rely on thermal processing to eliminate or inhibit the growth of pathogens, manufacturers must address food safety through a combination of preventive controls and intervention strategies. No single method is universally applied, and effective programs typically utilize multiple strategies to reduce risk.

Common pathogen reduction strategies used in raw pet food manufacturing may include:

- High Pressure Processing (HPP): A non-thermal food safety method that uses extremely high pressure to inactivate pathogens and extend shelf-life

- Bacteriophages: Viruses that infect specific bacteria by penetrating the cell membrane and replicating inside the cell, resulting in cell death. It is important to note that not all bacteriophages are Generally Recognized As Safe (GRAS) for use in pet food.

- Ozonation: The use of ozone gas (O3) to disinfect food, sanitize equipment, and increase shelf-life by reducing bacteria and other microbes

- Blast freezing: Rapid freezing to slow microbial growth, often used in conjunction with other control measures

- Acidulation: Organic acids are commonly used to lower pH and inhibit pathogen growth

- Probiotics: Beneficial microorganisms that may help competitively exclude pathogens

- Irradiation: Controlled radiation exposure to reduce microbial load

- Testing of incoming raw materials: Screening raw ingredients for pathogen contamination before they enter the production process

Each of these tools comes with its own limitations, regulatory considerations, and validation requirements. When evaluating the safety and quality of a raw pet food product, is critical to understand which controls are used and how they are managed in the production facility.

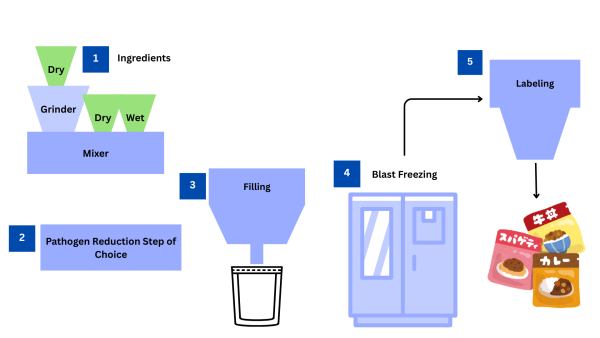

Raw Pet Food Manufacturing: Step-by-Step

- Ingredient preparation and grinding: Fresh and/or frozen meat, organs, and bones are ground or cut to a target particle size. These are combined with any additional ingredients, if applicable, such as vegetables, fruits, nuts or seeds, oils, eggs, and vitamin–mineral premixes.

- Pathogen reduction (if applicable): Depending on the formulation and food safety program, products may undergo pathogen reduction steps designed to reduce the presence of pathogens using one or more validated control strategies, as discussed above.

- Filling and sealing: The product is filled directly into pouches according to the target weight. Pouches are then heat-sealed under controlled conditions to limit exposure and maintain package integrity.

- Blast freezing (if applicable): Finished packages may be blast-frozen to rapidly reduce temperature and inhibit microbial growth, particularly for products intended for frozen distribution. ]

- Frozen storage: Finished products are stored under required frozen conditions (<40°F) until distribution.

Graphic by BSM Partners

Raw pet food isn’t inherently “better” or “worse” than other formats. Its quality and safety depend on ingredient selection and monitoring, manufacturing controls, and food safety programs.

The quality of a raw pet product is not determined by the word “raw” on the label, but by how well these systems are designed, validated, and executed. By understanding the process of how pet food is made, pet parents can make more informed decisions on what type of product will fulfill both their own preferences and their pet’s needs.

BSM Partners works across all pet food formats, including raw, frozen, fresh, and shelf-stable products. Our cross-functional expertise allows us to support companies at every stage of raw pet food development, from ingredient sourcing and supplier verification to food safety programs, process validation, and consumer education. Whether you are evaluating pathogen reduction strategies, strengthening preventive controls, or refining how you communicate processing and safety to pet parents, our team can help ensure your approach is scientifically sound, compliant, and aligned with your brand goals.

Follow us on LinkedIn for the latest updates on all things happening here at BSM Partners.

About the Author

Ada-Miette Thomas is a senior analyst at BSM Partners. She received both bachelor’s and master’s degrees in food science with an emphasis on nutrition. Ada-Miette conducted research with a focus on human nutrition and studied the effects of carbohydrate sources on markers of Metabolic Syndrome in adults.

This content is the property of BSM Partners. Reproduction or retransmission or repurposing of any portion of this content is expressly prohibited without the approval of BSM Partners and is governed by the terms and conditions explained here.