H5N1 and Pet Food: Navigating Challenges, Building Trust, and Taking Action

As the current outbreak of highly pathogenic avian influenza (H5N1) continues, the pet food industry has been put on high alert. Several pet food recalls related to the outbreak have troubled pet parents and tainted the reputation of brands involved.

To help all pet lovers navigate this challenge with confidence, BSM Partners put together two free webinars—one for pet parents, and one for industry professionals—through which our team of veterinary and food safety experts deconstructed the risk of H5N1 for pet food production, supply chain stability, pet health and safety, and consumer confidence. The webinar was supported by the World Pet Association (WPA) and Mud Bay, a leading independent pet retailer in the Pacific Northwest.

Here's what they had to say about mitigating the risk and impact of H5N1 on the pet food sector.

The Retail Perspective

Al Puntillo, Co-Chief Executive Officer of Mud Bay, kicked off the webinar with valuable insights into the delicate balance retailers must strike between transparency and reassurance.

"There's pretty much nothing any of us sell in any of our stores that is completely risk free," Puntillo explained. "You are constantly weighing risk and reward, and where we really feel this shakes out right now is—is there some risk? Yes, but it's pretty small. And our manufacturers need to step up and address that small percentage of the risk."

Recent media coverage has raised concerns among pet parents regarding the safety of some pet food products. Amid this skepticism, Puntillo emphasized the need for manufacturers to advocate for both consumers and industry partners by accurately sharing information and adopting robust safety measures specifically designed to combat H5N1.

"We have seen the veterinary community be very skeptical of raw foods to begin with, and this is going to fuel that if we do not have all the protocols in place, the testing to say we're addressing it. It's not enough just for us to say, 'Hey, this was only a couple of incidents. We don't think this is a big deal.'"

This perspective highlights a critical insight: industry members must prepare not only for current consumer concerns, but also for what Puntillo described as the "second wave" of scrutiny likely to come from veterinarians and other pet health professionals in the near future.

Understanding H5N1

The first step to understanding how we can combat the spread of H5N1 is to understand how this virus is most likely to spread. Dr. Katy Miller, DVM, CVFT, CVNAN, CPFFCP, PCQI, PAS, Director of Veterinary Services at BSM Partners, broke this down for attendees, noting that while H5N1 primarily affects waterfowl and poultry, its recent spread to mammals—including dairy cows and domestic cats—is worrying.

Two key characteristics make this virus particularly concerning:

- It's highly pathogenic, killing about 100% of birds within 48 hours of infection.

- While not primarily a mammalian disease, cats appear particularly susceptible.

“Luckily, this isn't a mammal disease, so it doesn't want to live in mammals and reproduce… but we are seeing that cats are particularly susceptible to this virus, and it is particularly dangerous if they get it,” Dr. Miller shared.

Staying One Step Ahead

Because H5N1 is considered highly pathogenic, the impact it has on poultry supply chains will have a ripple effect across the food supply chain, from eggs and poultry products in the grocery store to dried eggs and other poultry-derived products in your pets’ bowl.

For example, Dr. Quest emphasized that H5N1's high mortality rate currently is handled by widespread depopulation of birds, which inevitably affects the availability of poultry-derived products.

"It's going to affect eggs, potentially even affect some of the skeletal poultry meats as well, if the broiler industry becomes more affected,” Dr. Quest noted.

Eggs, in fact, are expected to be a pain point for pet food manufacturers, explained August Konie, MS, MBA, Principal of BSM Assurance.

"A lot of the U.S. supply for egg products or dried egg powder... comes from what we call the breakers of shelled eggs. So, they rely on the supply of table eggs... when you decrease the population or you depopulate those egg-laying hens for table eggs… this obviously is going to affect the availability of those kinds of products,” Konie said.

Thus, manufacturers will need robust contingency plans for sourcing poultry-derived ingredients during this outbreak. A diversified sourcing strategy, alternative ingredient options, and a clear understanding of import/export restrictions will all help keep products on-shelf.

Konie also offered practical advice for how manufacturers can minimize disruptions along the supply chain, including the importance of diversifying your ingredient sources geographically, working flexibility and ingredient alternatives into your sourcing network, holding suppliers accountable for food safety, and requesting documentation for raw material testing.

Cross-Contamination: Identifying Risk Points

Konie also highlighted the multiple risk vectors pet food manufacturers must consider when addressing H5N1 risk, including:

- Direct ingredient risks for poultry proteins and egg products

- Cross-contamination, particularly among employees working in rural areas with exposure to farms

- Facility setup, workflow, and sanitation processes

"The risks are in the raw material sourcing itself… but let's not also forget that there is a risk of cross-contamination," Konie noted. "A lot of these pet food manufacturers are set in rural areas where the employees themselves would have contact with either farms, different farm flocks... or they could be in livestock."

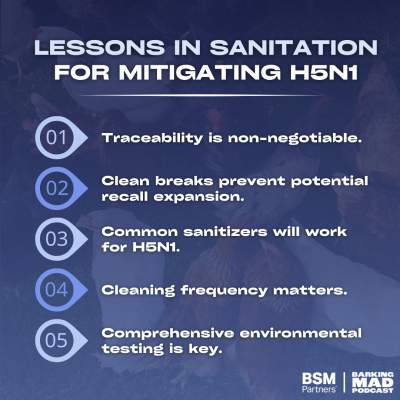

He continued to showcase his food safety and quality expertise in discussion practical sanitation protocols, emphasizing several critical points.

Konie touched on the human element in preventing contamination, stressing the importance of a robust food safety culture across the manufacturing workforce. To support such a culture, employees of food and pet food manufacturing operations must consider how their routines at work and at home contribute to the risk of spreading H5N1.

For example, limiting exposure to backyard poultry or dairy cows, proper handling and storage of work apparel and gear, and maintaining established workflows with strict separation between pre-and post-cooking processes in the plant can all reduce cross-contamination and keep our food supply chains and families safe.

Processing for Protection

The pet food industry already utilizes a range of sanitation and processing methods that can mitigate the virus in manufacturing settings. While Konie shared the sanitation side of the equation, Dr. Quest went on to discuss effective pet food processing methods.

"Extrusion cooking, making kibble, definitively inactivates the virus,” he said. “Retort cooking, canned trays, pouches, those types of products, definitively inactivates the virus. Baking processes definitively inactivate the virus."

However, for alternative format products that do not undergo a “kill step” or any sort of high-heat processing, multiple approaches can be effective, such as:

- High-pressure pasteurization (HPP)

- Acidification (in combination with HPP)

- Radiation (at proper dosages)

Dr. Quest also shared an important regulatory update. In January, the US Food and Drug Administration announced it has made it required for pet food manufacturers to account for the risk of H5N1 in their documented food safety plans. This announcement will likely manifest through:

- Increased sampling from the FDA and USDA

- Mandatory pre- and post-production testing

- More rigorous risk assessments

- Changes to third-party audit systems

"I wouldn't be surprised if you see an additional notice from the USDA mandating the same thing,” Konie added.

And while implementing new food safety measures inevitably comes at a cost, Dr. Quest reframed this development as an investment.

"What you're doing is you're actually investing in your brand... and then for the co-manufacturers and the plants themselves, you're investing in their overall food safety plan as well... a robust food safety plan is always going to pay dividends,” he shared.

Building Consumer Trust Through Transparency

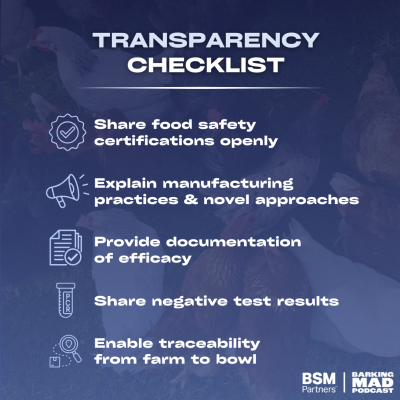

In wrapping up the webinar, Dr. Miller reiterated a crucial aspect of the H5N1 outbreak—maintaining consumer confidence during uncertain times. The best course of action here, she suggested, is transparency.

“In some cases, [pet parents are] very skeptical that we're doing something behind the curtain or we're not speaking the truth, and the one way to mitigate that is with as much transparency as possible through every step of food production that you can and the steps that you're taking to ensure that a safe product is being delivered to them,” Dr. Miller said.

Achieving Industry-Wide Resilience

H5N1 presents both challenges and opportunities for the pet food industry. Whether you're diversifying your supply chains, enhancing your testing protocols, or reinforcing your commitment to transparency, the time to act is now.

Remember that risk mitigation is a shared responsibility across the entire value chain. Manufacturers must take proactive steps to ensure safe ingredient testing, rigorous sanitation protocols, transparent testing, and clear communication with retailers and consumers.

With regulatory oversight ramping up around H5N1, preparedness isn't just smart business—it's essential for compliance, and for maintaining consumer trust. The manufacturers that invest in food safety and commit to transparency will not only protect pets and consumers but also build stronger trust and relationships for their brands.

At BSM Partners, we're committed to helping the industry navigate these challenges with data-driven insights and practical strategies. Together, we can ensure our industry remains safe, secure, and resilient in the face of this and future challenges.

Follow us on LinkedIn for the latest updates on all things happening here at BSM Partners.

About the Author

Jordan Tyler is the Director of Media at BSM Partners and co-host of the Barking Mad podcast. She has more than seven years of experience reporting on trends, best practices and developments in the North American pet nutrition industry. Jordan resides in Bentonville, Arkansas, with her husband and their three furry family members.

This content is the property of BSM Partners. Reproduction or retransmission or repurposing of any portion of this content is expressly prohibited without the approval of BSM Partners and is governed by the terms and conditions explained here.